Key Benefits of Epoxy Flooring for Garage Floors

- UV stable topcoat that maintains a glossy finish and won’t yellow or fade over time

- Exceptional abrasion and impact resistance

- Excellent chemical resistance to oil, gas, salt and other chemicals

- Seals surface / prevents surface failures

- Allows for easier cleaning

- Provides an anti-slip surface

- Creates a dust free environment

- Showroom quality finish

- Protects your investment

Epoxy flooring is one of the most popular options when it comes to concrete coatings and finishing. It has many great qualities that can be adapted to a number of different environments to suit nearly every need. There are a few key things to know when you’re considering having an epoxy floor installed.

Achieving a Durable Garage Floor: The Benefits of Shot Blasting and Epoxy Coatings

The concrete floor in your garage is too smooth to allow a coating to stick to it, this is by design to prevent staining and make it easier to clean. Since we want our coatings to stick and never come off, we use a process called shot blasting to put a coarse texture, or profile, on the concrete. The texture created by shot blasting allows our coatings to bond so aggressively that concrete will fracture before the coating pulls off. Shot blasting is also completely dustless and environmentally friendly as it recycles and reuses the steel blast media inside of itself.

After shot blasting, we’ll fill any cracks and deficiencies in the concrete so that your finished floor is a smooth, seamless masterpiece. We always apply a 100% solids epoxy base coat to the floor. Epoxy has higher levels of adhesion and greater moisture tolerance compared to polyurea and polyaspartic.

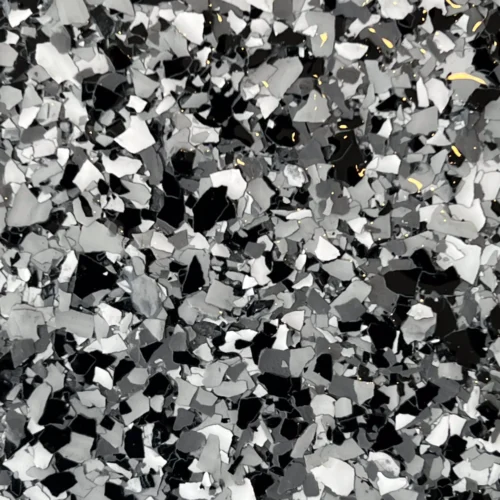

Most customers opt for a decorative flake finish. The texture provided by the flake delivers just the right level of durability, slip resistance when wet, and ease of cleaning when dirty. We apply a UV stable, polyaspartic clear coat to the floor which provides excellent levels of abrasion resistance, chemical resistance, and overall resilience. Not to mention outstanding aesthetics. Our floors are maintenance free and only require water and a squeegee to clean.

As the most established name in concrete coatings in the Okanagan, our team, along with the most high-tech equipment available and most premium products on the market, will provide you with a garage you can be proud of at a price you’ll love.

Epoxy Flooring Samples

Zonda

Domino

Shoreline

Mushroom

Sahara

Nightfall

Granite

Epoxy coatings can provide a smooth glossy finish and are commonly used in the following:

- Mechanic Shop

- Wineries & Breweries

- Residential Floors

- Garages

- Warehouses

- Health Care Facilities

- Food Processing Plants

- Airplane Hangers